165 Steam Hose

Steam hoses are designed to withstand the high temperatures and moisture of saturated and superheated steam in steam service applications.The hose is very flexible and it is resistant to vibration. It is composed of three parts: tube, reinforcement and cover.

The tube is made from high quality black and smooth synthetic rubber, mainly EPDM, which is highly resistant to high temperature. Therefore, the hose can deliver steam safely. The reinforcement is made from one layer or two layers of high tensile and high strength braided steel wire, making the hose have solid structure and work well in high pressure environment. The cover is made from high quality EPDM, making the hose resistant to abrasion, corrosion, aging, weather, ozone and high temperature. Besides, the hose is resistant to bursting, cracking and crushing even under large pressure difference and accidental exposure to flame.

Application:

Reinforced steam hose, designed for saturated steam with 6 bar in maximum working pressure; Exhausting the water after using to extend the service life.

Temperature:-40℃ to +165℃(-40℉ to +329℉)

Tube:Black, smooth, Resistance to high temperature saturat-ed steam EPDM synthetic rubber.

Reinfrocement: High strength synthetic cord

Cover: Black, smooth(wrapped finish)synthetic EPDM rubber. High temperature, weathering and ozone resistant.

Optional Request: High strength synthetic helix wire, Black cover, Negative pressure resistance.

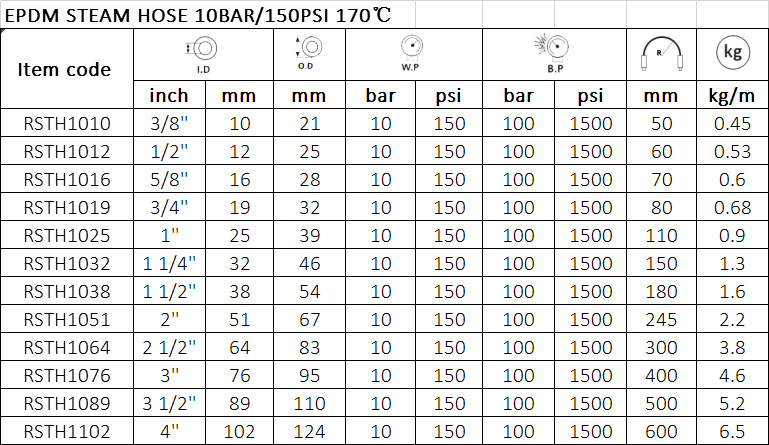

165 steam hose specification

Material: Good quality materials make our steam hose steady performance.

Production: Advanced technology and equipment to make the best quality 165 steam hose.

Laboratory:

Our factory has strong quality control team, we set up advanced laboratory.

Before the mass production, we test each batch of raw material.

After the production, we test each hose to guarantee a 100% qualification.

Each hose tested at 2 times of working pressure.

We do everything possible to supply good quality goods for our customer.

Packaging: After finishing the steam hose production, we will pack the hose.

In general, the packing will use woven bag and plastic film.

Special packing is available according to customers’ requirements.

Market & Exports: Our product has exported to over 30 countries,

including the United States, Britain, Brazil, Russia and so on.

Trade shows: we participate in overseas exhibitions every year.

1).Strong R&D team

Orientflex founded in 2006, set up advanced laboratory, is committed continuously improve production technology,the development of new formula, improve production efficency and product quality.

2) Advanced equipment from Italy

Orient flex imported most advanced industrial hose production line from Italy,13 braiding machine are automatically computer controlled, large diameter dredging hose production line are designed by Italian engineers.

3) strict quality inspection

Strong quality control team,advanced laboratory,test each batch of material, strict production process control for each working prodedure,100% full inspection before delivery of finished products. to provide 100% quality products for customers.

4)strong and experienced export team

International department has 15 experienced salesman who speak English,

Russian,Spanish,Japanese, with more than 10 years experience,export to more than 50 countries, we know your market demand very well,we can provide products suitable for your market,we can help you to make money.